Pulse Echo Integrity Test (PIT)

The

Pulse Echo Integrity Test is so quick and simple to execute that it permits checking all the foundation elements of a construction site for anomalies. It is performed with the Pile Integrity Tester™ on any type of concrete deep foundation.

Pulse Echo Integrity Test is a non destructive pile testing method that verifies the integrity of driven concrete or timber piles, auger cast-in-place piles and drilled shafts. If major defects exist, the test estimates their magnitude and location; it may also determine pile length.

The Pulse Echo Integrity Test, also known as Pile Integrity Test, Sonic Echo Test and Low Strain Test, is normally performed after pile installation and curing. It requires minimal pile preparation, and has been routinely used worldwide for many years. Because of its simplicity, speed of execution and low cost, it can be performed on 100% of the piles on a given job site.

The pile top has to be hit with a hand held hammer. The impact of the hammer generates a compressive stress wave in the pile, and an accelerometer placed on top of the pile monitors the motion associated with this wave. The stress wave propagates down the pile shaft, and is reflected when it encounters either the pile toe or a non-uniformity of the shaft. These reflections cause a change in the acceleration signal measured on the pile top, which is picked up and processed by the Pile Integrity Tester™ (PIT) by Pile Dynamics and interpreted by an experienced SLP engineer.

SLP performs this foundation integrity test in accordance with ASTM D5882-07 – Standard Test Method for Low Strain Integrity Testing of Piles.

Cross-Hole Sonic Logging (CSL)

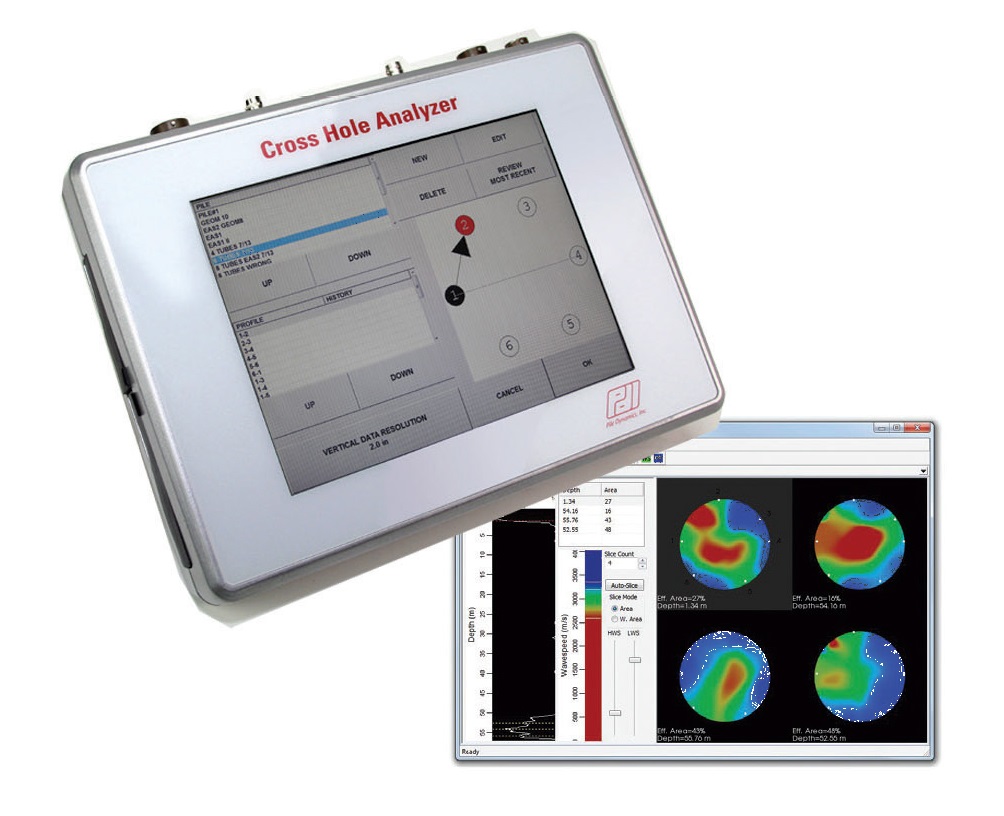

Cross-Hole Sonic Logging is used to verify the homogeneity and integrity of concrete in deep foundation such as bored piles, drilled shafts, concrete piles or augercast piles. This method can also be extended to diaphragm walls, barrettes, dams etc. It assures the absence of cracks and voids and verifies concrete quality on elements built with inspection tubes. Field results are complemented by Tomography analysis.

Drilled shafts are prepared for integrity testing by CSL during their construction, by installation of at least three tubes of 2 inch inside diameter. These tubes are usually attached to the reinforcement cage along the full length of the shafts. After concrete has been poured, the tubes are filled with water.

Cross-Hole Sonic Logging is performed with the Cross-Hole Analyzer™ (CHA) by Pile Dynamics. Starting at the bottom of the shaft, a transmitter emits an ultrasonic signal in one tube. The signal is sensed some time later by the receiver in another tube. Poor concrete between the tubes will delay or completely disrupt the signal. The sensors (transmitter and receiver) are than moved some distance upward along the shaft and the process repeated until the entire shaft length is scanned. The engineer repeats the test for each pair of tubes, allowing for the investigation of defects both along the length and by quadrant.

SLP performs this foundation integrity test in accordance with ASTM D6760-02 – Standard Test Method for Integrity Testing of Concrete Deep Foundations by Ultrasonic Crosshole Testing.

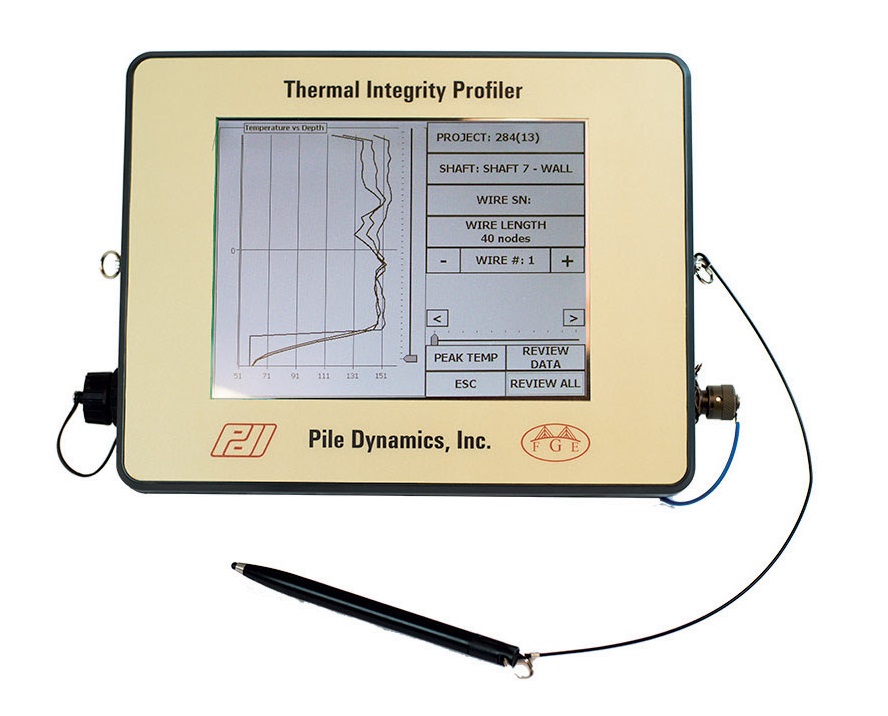

Thermal Integrity Profiling (TIP)

Thermal Integrity Profiling is a technology that utilizes the heat generated by curing of concrete to assess the integrity and quality of drilled shafts, augered cast in place piles (ACIP) and other concrete foundations. From the test results, necks, bulges, variations in concrete cover and the as-built shape of the shaft, including steel cage eccentricities, can be characterized. Drilled shafts and ACIP piles are prepared for Thermal Integrity Profiling during their construction, by the installation of Thermal Wire®

brand cables or access tubes. We perform this test using a Thermal Integrity Profiler™ (TIP) by Pile Dynamics. When shafts are equipped with Thermal Wire cables, temperatures are automatically sampled throughout the concrete hydration process starting immediately after casting. We typically retrieve the data for analysis and reporting after 12 to 48 hours depending upon shaft diameter and mix design.

SLP performs this foundation integrity test in accordance with ASTM D7949–14 - Standard Test Methods for Thermal Integrity Profiling of Concrete Deep Foundations.